Manufacturing

Updated on 2023-08-29T12:01:53.862053Z

What is manufacturing?

Manufacturing is turning raw materials into finished goods employing instruments, machinery, labour and chemical or biological processing. In addition, it is the production of more complex elements by selling essential items to producers to manufacture such items as household appliances, planes or vehicles.

Manufacturing is critical not just for creating and distributing goods in the marketplace but also for economic reasons.

Manufacturing engineering or process might turn raw resources into completed goods, and this process starts with material selection and product development. Then, to produce the finished goods, the materials could be modified during several production steps.

Manufacturing is easy to run; an owner purchases parts or raw materials and uses them to create a finished item. However, to run a business, the producer must cover costs, satisfy demand, and produce items to meet the market's supply.

Large-scale manufacturing permits for the mass production of various items that integrate assembly-line methods and better technology. Effective manufacturing technologies enable producers to benefit economies of scale, producing many units at a lower cost.

Furthermore, it is a value-adding process that permits enterprises to sell finished goods for more than the cost of the raw materials used. The conference board routinely reports on it, and economists thoroughly review it.

When analysing the contribution of production in the economy, government statisticians and economists employ different ratios. For instance, manufacturing value added (MVA) is a metric that compares the industrial output to the size of the whole economy. Moreover, it is calculated as a percentage of gross domestic product.

Highlights

- Manufacturing is turning raw materials into finished goods employing instruments, machinery, labour and chemical or biological processing.

- Manufacturing engineering or process might turn raw resources into finished goods, and this process starts with material selection and product development.

- Large-scale manufacturing permits for the mass production of various items that integrate assembly-line methods and better technology.

Frequently Asked Questions (FAQs)

What are the types of manufacturing?

Source: © Industryviews | Megapixl.com

Make-to-Stock (MTS)

In this method, a factory makes goods that are stored in showrooms. This implies that a market for the commodities must be anticipated for items to be created ahead of time and available for the consumer.

Nevertheless, making too many goods might entail that excess stock must be sold at a loss, whilst producing too few goods may mean that the market has been missed and sales do not compensate expenses.

Make-to-Order (MTO)

The strategy permits the firm to wait until orders are received before going into production. This makes managing stockpiles and responding to market demand much easier.

On the other hand, consumers would have to wait for their items to be made, while producers would require a continual supply of orders to keep the factory running and profitable.

Make-to-Assemble (MTA)

This strategy is quite similar to make to stock, except the firm will be making component parts in expectation of assembly orders. All of this means that the producer is ready to fulfil customer's orders when they come, but if there is no demand, the producer may end up with a stockpile of unwanted parts.

Furthermore, each type of production has its own set of hazards linked to demand and supply. Manufacture too many items, and the market will be inundated, resulting in lower prices and revenues. Making small quantities of goods will cause the customer to move elsewhere, implying that profit potential has been lost. Quality control is an integral part of any production process to safeguard the reputation of a brand's identity and commodities. A booming production firm needs a well-balanced sale, inventory management, quality control, and manufacturing costing.

Source: Copyright © 2021 Kalkine Media

What is an example of manufacturing?

Manufacturing is the method of introducing new products from raw materials or elements. For example, car companies, bakers, footwear makers, and tailors are all manufacturing instances because they develop items rather than providing services.

While mining is not production, as they don't change commodities into new goods. Although construction seems to be a manufacturing process, it is essentially a separate category and is not regarded as an element of production.

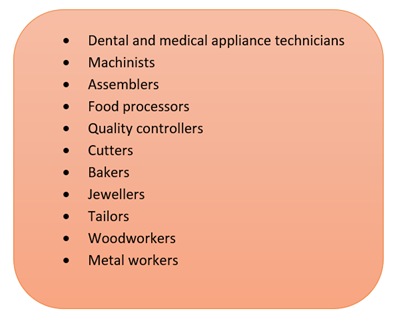

Manufacturing jobs include the following:

Source: Copyright © 2021 Kalkine Media

What does it mean to be a manufacturer?

The manufacturer is an individual or firm that creates finished goods from raw materials by employing various equipment, tools, and procedures. It then sells them to retailers, customers, distributors, wholesalers, or other manufacturers to produce more complex goods.

Manufacturers must adhere to product certification criteria. The goods being produced are subjected to performance and quality assurance tests as part of this procedure. The certification bodies place a strong emphasis on meeting all applicable international standards. It's a method that will improve consumer protection.

A manufacturer must adhere to all quality assurance standards to prevent future customer lawsuits and grow client happiness.

Source: © Scanrail | Megapixl.com

What is the history of manufacturing?

Manufacturers are known to be an essential part of the nation's economy. It has a long history that could be traced back to ancient times. For centuries, moreover, the traditional manufacturer was a single skilled artisan with helpers. The secrets of manufacturing were kept by each artisan, who only passed on their skills to apprentices. Manual processes were the only ones available for production.

For manufacturers, the industrial revolution was a watershed moment. The establishment of new technologies was one of the outcomes of the industrial revolution. For example, steam engines permitted the mechanisation of manufacturing, which boosted the number of commodities produced. Consequently, at the turn of the 20th century, producers had shifted their focus to mass production.

Production is now an essential component of a thriving economy. Modern producers have traditionally been linked with mass production. However, technological improvements enabled the mechanisation of manufacturing processes, which enhances overall productivity and effectiveness.